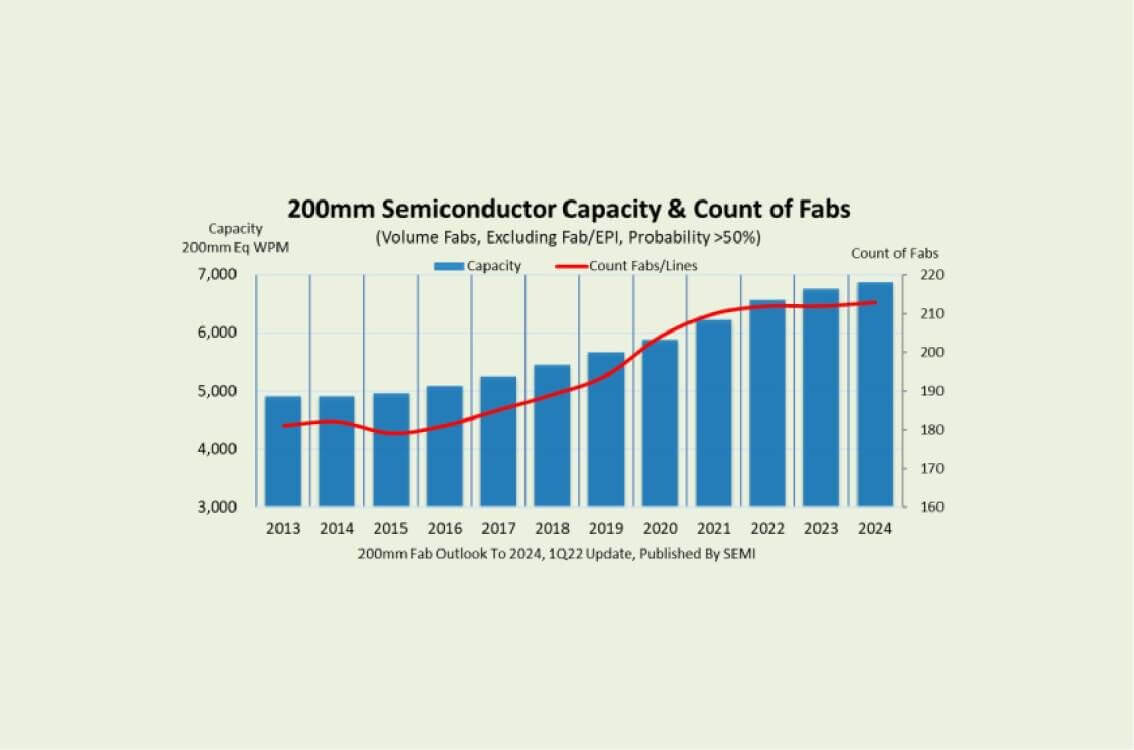

According to SEMI's latest 200mm Fab Outlook Report, from early 2020 to the end of 2024, global semiconductor manufacturers are expected to increase 200mm fab capacity by 1.2 million wafers, or 21%, to a record high of 6.9 million wafers per month.

SEMI pointed out that after climbing to $5.3 billion last year, 200mm fab equipment spending is expected to be $4.9 billion in 2022 as 200mm fab utilization remains at high levels and the global semiconductor industry works to overcome the chip shortage.

“Wafer manufacturers will add 25 new 200mm lines over the five-year period to help meet growing demand for applications such as 5G, automotive and Internet of Things (IoT) devices that rely on devices like analog, power management and display driver integrated circuits (ICs), MOSFETs, microcontroller units (MCUs) and sensors,” said Ajit Manocha, SEMI president and CEO.

The SEMI 200mm Fab Outlook Report also reveals that foundries will account for more than 50% of fab capacity worldwide this year, followed by analog at 19% and discrete/power at 12%. Regionally, China will lead the world in 200mm capacity with 21% share in 2022, followed by Japan with 16% and Taiwan and Europe/Mideast at 15% each.

Equipment investments are projected to remain above $3 billion in 2023, with the foundry sector accounting for 54%, followed by discrete/power at 20% and analog at 19%.

The SEMI 200mm Fab Outlook Report lists more than 330 fabs and lines and includes 64 changes across 47 fabs since its most recent update in September 2021.

For more information on the report, please visit https://www.semi.org/en/products-services/market-data/200mm-fab-outlook.

All Comments (0)