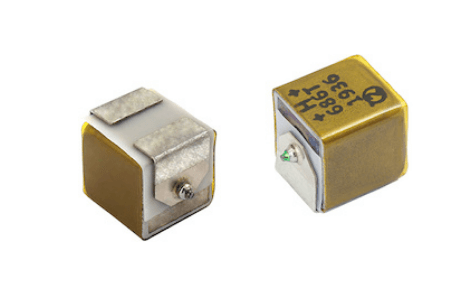

Vishay Intertechnology recently introduced a new series of HI-TMP® surface-mount wet tantalum capacitors with high operating temperatures to +200 °C in the compact C case code. Offering a smaller size and footprint than equivalent through-hole and overmolded high temperature devices, the T24 series is designed to utilize board space more efficiently and deliver increased reliability for oil exploration, and military and aerospace radar applications.

Measuring 9 mm by 7.1 mm by 7.4 mm, the capacitors released today feature a tantalum metal case with a glass to tantalum hermetic seal. Optimized for timing, filtering, energy hold-up and pulse power applications, the devices offer improved thermal shock capability to 300 cycles and provide a longer life of 2,000 hours at +200 °C, eliminating the need to utilize larger through-hole devices in demanding environments.

The T24 series features 200 °C derated voltage ratings of 45 VDC and 75 VDC, with capacitance values of 33 µF and 10 µF, respectively, and capacitance tolerance of ± 10 % and ± 20 % standard. The devices operate over a temperature range of -55 °C to +85 °C, to +200 °C with voltage derating, and provide maximum ESR down to 2.5 Ω at 120 Hz and +85 °C. The capacitors are RoHS-compliant, halogen-free, and Vishay Green.

Samples and production quantities of the T24 series are available now, with lead times of 10 weeks. More information please visit https://www.vishay.com/ppg?40261.

All Comments (0)