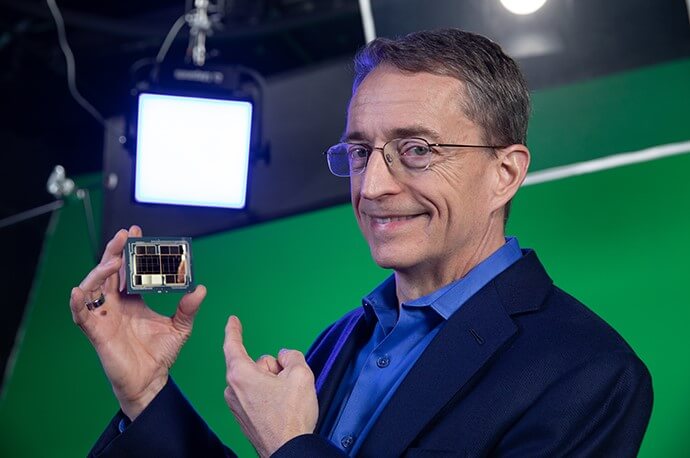

Intel CEO Pat Gelsinger announced on March 23 that Intel will provide foundry services and plans to become a major foundry supplier in the United States and Europe to provide services to customers around the world. At the same time, Intel announced its expansion plan in chip manufacturing and will first invest US$20 billion to build two new fabs in Arizona, USA.

Gelsinger said that Intel will make major changes to the existing IDM model and will be committed to advancing the IDM 2.0 model in the future. According to Gelsinger, Intel’s IDM mode 2.0 mainly includes the following:

- Intel’s global, internal factory network for at-scale manufacturing is a key competitive advantage that enables product optimization, improved economics and supply resilience. Today, Gelsinger re-affirmed the company’s expectation to continue manufacturing the majority of its products internally. The company’s 7nm development is progressing well, driven by increased use of extreme ultraviolet lithography (EUV) in a rearchitected, simplified process flow. Intel expects to tape in the compute tile for its first 7nm client CPU (code-named “Meteor Lake”) in the second quarter of this year. In addition to process innovation, Intel’s leadership in packaging technology is an important differentiator that enables the combination of multiple IPs or “tiles” to deliver uniquely tailored products that meet diverse customer requirements in a world of pervasive computing.

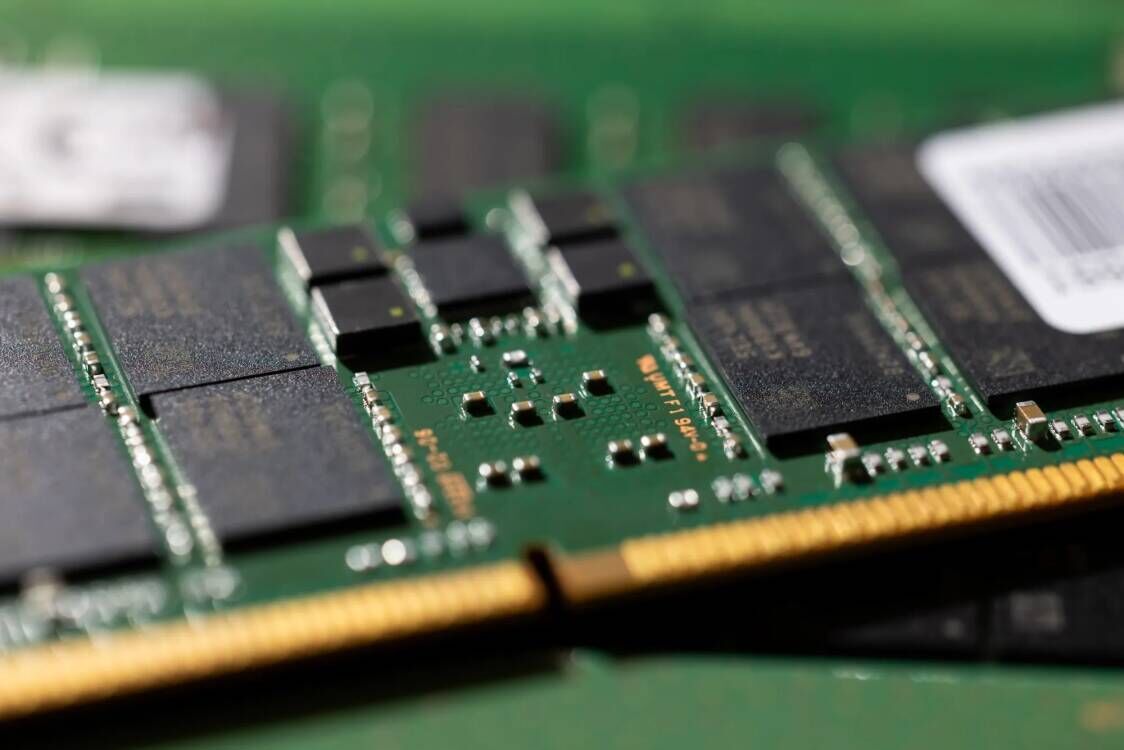

- Expanded use of third-party foundry capacity. Intel expects to build on its existing relationships with third-party foundries, which today manufacture a range of Intel technology – from communications and connectivity to graphics and chipsets. Gelsinger said he expects Intel’s engagement with third-party foundries to grow and to include manufacturing for a range of modular tiles on advanced process technologies, including products at the core of Intel’s computing offerings for both client and data center segments beginning in 2023. This will provide the increased flexibility and scale needed to optimize Intel’s roadmaps for cost, performance, schedule and supply, giving the company a unique competitive advantage.

- Building a world-class foundry business, Intel Foundry Services. Intel announced plans to become a major provider of U.S.– and Europe-based foundry capacity to serve the incredible global demand for semiconductor manufacturing. To deliver this vision, Intel is establishing a new standalone business unit, Intel Foundry Services (IFS), led by semiconductor industry veteran Dr. Randhir Thakur, who will report directly to Gelsinger. IFS will be differentiated from other foundry offerings with a combination of leading-edge process technology and packaging, committed capacity in the U.S. and Europe, and a world-class IP portfolio for customers, including x86 cores as well as ARM and RISC-V ecosystem IPs. Gelsinger noted that Intel’s foundry plans have already received strong enthusiasm and statements of support from across the industry.

To accelerate Intel’s IDM 2.0 strategy, Gelsinger announced a significant expansion of Intel’s manufacturing capacity, beginning with plans for two new fabs in Arizona, located at the company’s Ocotillo campus. These fabs will support the increasing requirements of Intel’s current products and customers, as well as provide committed capacity for foundry customers.

In addition, Intel plans to announce the next phase of capacity expansion plans in the United States, Europe and other regions of the world within this year.

To realize the IDM 2.0 vision. Intel and its eco-partner IBM jointly announced an important research cooperation plan-focusing on the creation of the next generation of logic chip packaging technology, the project aims to accelerate the innovation of semiconductor manufacturing.

All Comments (0)