December 17, 2025 /SemiMedia/ — ROHM has introduced two new motor driver integrated circuits designed for brushed DC motors, targeting growing demand for energy-efficient motor control in home appliances and industrial equipment.

Electrification drives demand for efficient motor control semiconductors

The launch comes as electrification continues to expand across white goods and office automation systems, pushing semiconductor suppliers to deliver motor control solutions that balance power efficiency, functional flexibility and compact system design.

The newly released BD60210FV and BD64950EFJ are positioned to support a broad range of applications, including refrigerators, air conditioners, printers and robotic vacuum cleaners. Both devices feature ultra-low standby current consumption, helping reduce overall system power loss during idle operation.

Dual and single H-bridge designs target diverse DC motor applications

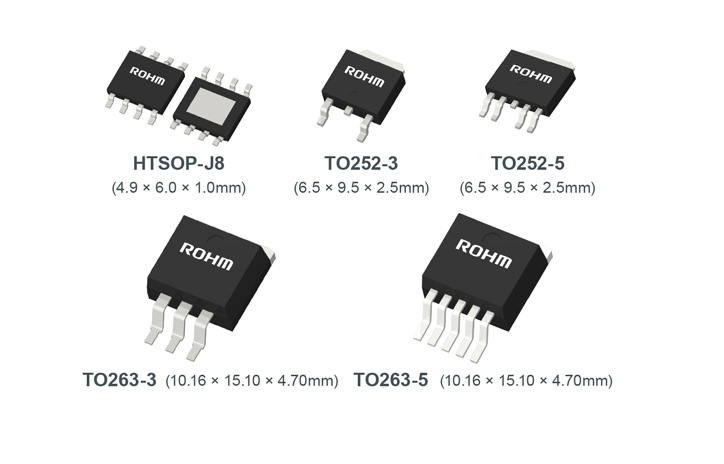

The BD60210FV integrates a dual H-bridge configuration and supports direct PWM control, enabling it to drive two brushed DC motors, a bipolar stepper motor or solenoid loads. Its architecture eliminates the need for a boost circuit, reducing external component count and board space. The device operates across an 8V to 18V input range, delivering 1A continuous current per phase and up to 4A peak.

For higher-voltage and higher-power systems, the BD64950EFJ adopts a single H-bridge design and supports both direct PWM and constant-current PWM control. With a breakdown voltage of 40V and continuous output current of 3.5A, the device is suited for 24V brushed DC motor applications, while its low on-resistance helps limit heat generation.

ROHM said both motor driver ICs are now in mass production, with a sample price of about US$1.5 per unit, as the company continues to expand its portfolio of power and motor control semiconductors for appliance and industrial markets.

All Comments (0)