May 15, 2025 /SemiMedia/ — Samsung Electronics is considering outsourcing low-end photomask production to reallocate internal capacity toward advanced lithography used in next-generation memory chips.

The company is evaluating suppliers for i-line and KrF masks, including Tekscend Photomask, a unit of Japan’s Toppan Holdings, and PKL, part of U.S.-based Photronics. The review is expected to conclude in the third quarter.

Samsung has traditionally produced all photomasks in-house to guard against technology leakage. However, aging internal equipment and reduced technological risk are prompting a shift in strategy. Outsourcing less critical masks would free up resources for ArF and EUV masks required in cutting-edge manufacturing.

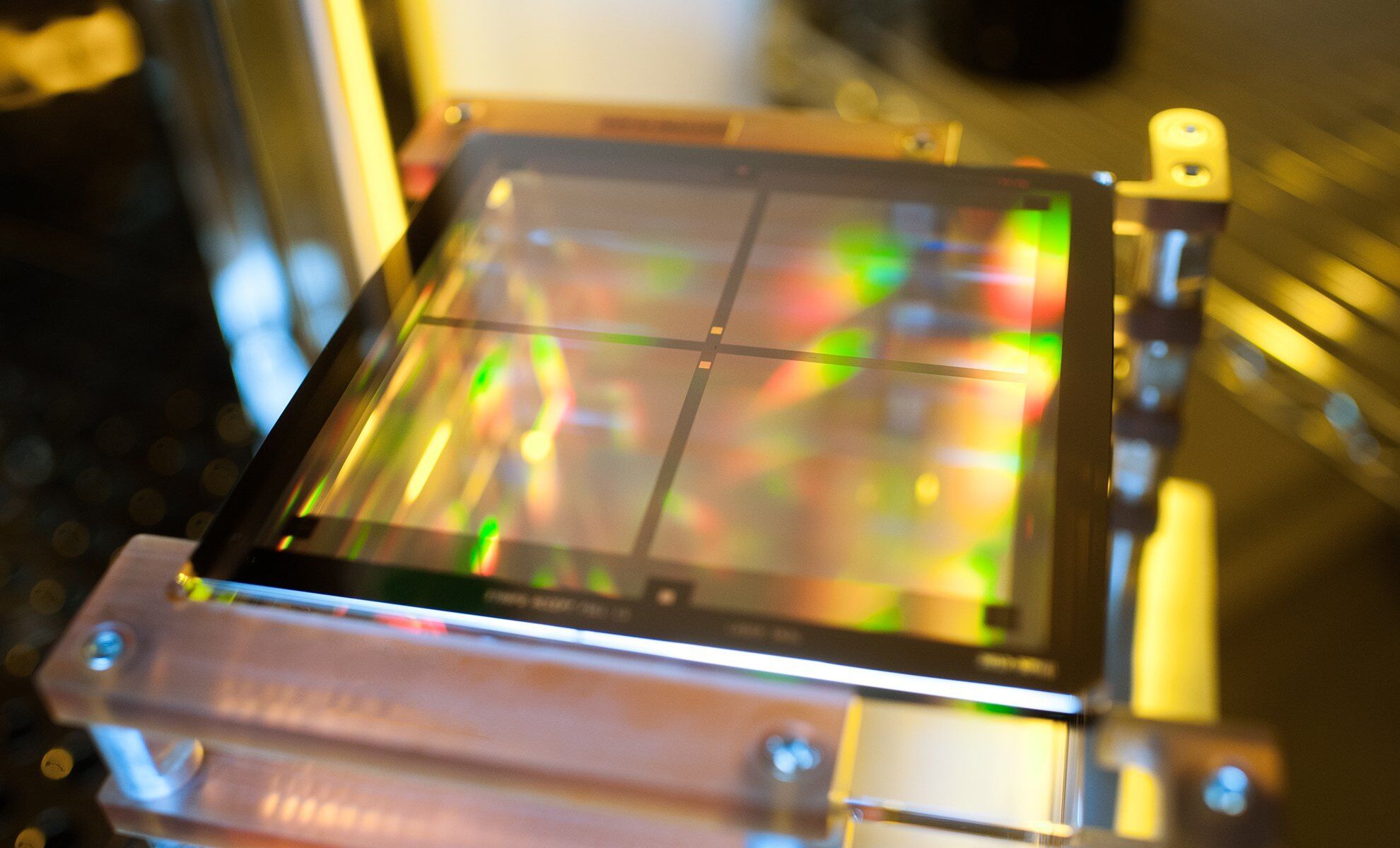

Photomasks, which transfer circuit patterns onto silicon wafers, are classified by light wavelength. Shorter wavelengths such as EUV (13.5nm) enable finer resolution, while i-line (365nm) and KrF (248nm) support mature process nodes.

South Korea’s photomask market is estimated at KRW 700 billion, with local fab utilization exceeding 90%. Rising demand from Chinese fabless firms has tightened supply. Industry sources warn that Samsung’s outsourcing could increase pressure on local foundries like DB Hitek seeking access to available photomasks.

All Comments (0)