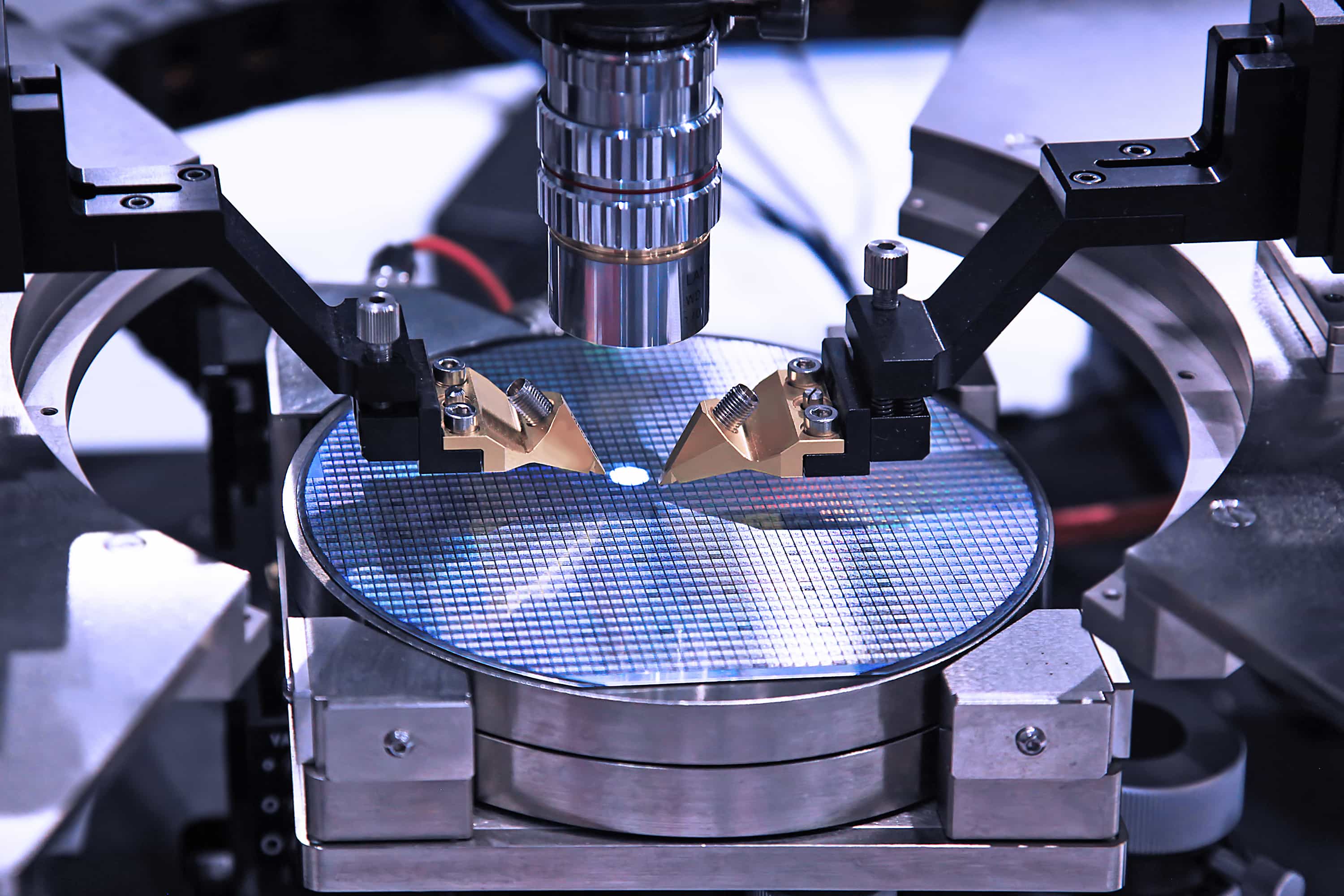

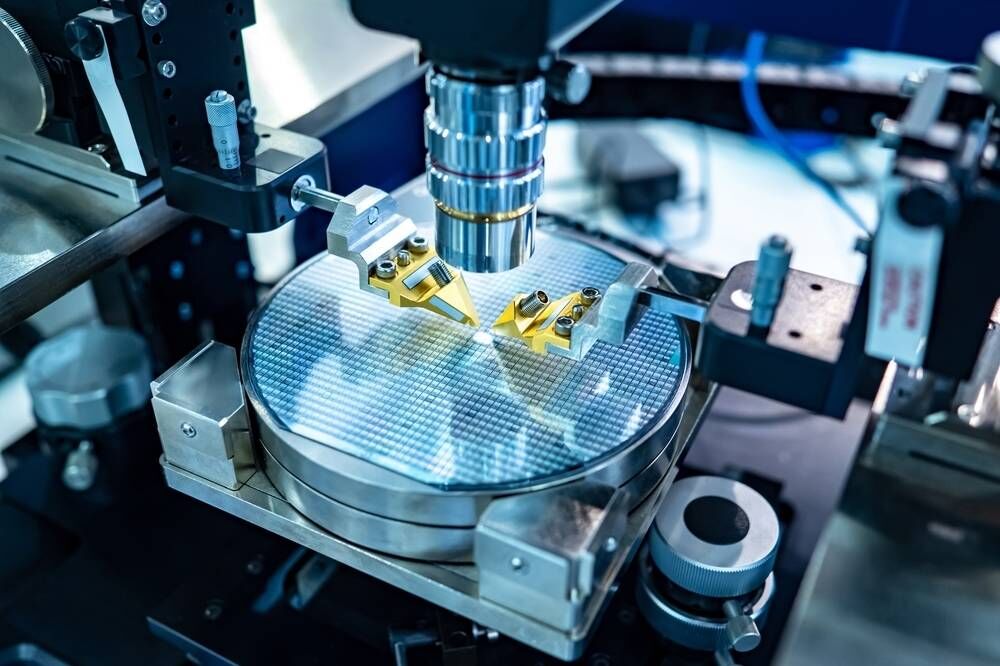

According to reports, the lead time of semiconductor production equipment has been extended to 18 to 30 months, and the overall expansion plans of wafer foundries such as TSMC, UMC, PSMC, VIS, SMIC, and GlobalFoundries will be forced to extend by about 2 to 9 months. It is expected that the year-on-year growth rate of wafer production capacity will drop to 8% in 2023.

The report pointed out that before the outbreak of Covid-19, the lead time of semiconductor production equipment was about 3 to 6 months. Since 2020, the border control implemented by various countries due to the epidemic has led to logistics blockage, and strong demand has driven the production expansion of semiconductor manufacturers. For these reasons, the lead time has been extended again to 12 to 18 months.

In 2022, affected by the conflict between Russia and Ukraine, logistics blockage, and insufficient semiconductor chip production capacity, the shortage of raw materials and chips affected the production of semiconductor equipment.

Except for EUV lithography equipment with a fixed annual output, the lead time of other equipment has been extended to 18 to 30 months. Among them, DUV lithography equipment is the most affected, followed by CVD/PVD deposition and etching equipment.

The report further pointed out that at present, semiconductor manufacturers mainly rely on production adjustment and resource reallocation to support capacity utilization. The expansion of wafer foundries is delayed by factors such as equipment delivery delays and plant construction delays, which will cause the year-on-year growth rate of global wafer foundry capacity to drop to 8% in 2023.

All Comments (0)