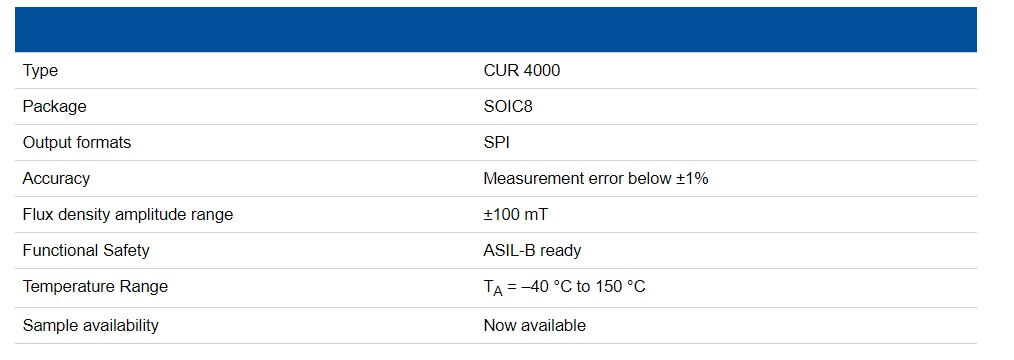

TDK recently announced the launch of the CUR 4000 Hall-effect sensor. The sensor, developed for highly accurate current measurements in automotive and industrial applications, offers non-intrusive, galvanic isolated contactless current sensing. These features will contribute to the future of high-voltage systems of hybrid and electric vehicles (xEV). The product is suited for DC and AC measurements and overcurrent detection in high-power battery monitoring applications and can measure dynamic current ranges up to ≥2000 A.* For these kind of measurement tasks, CUR 4000 comes with different configurable modes for linear core-based and differential coreless application setups.

The sensor's production is planned for the second quarter of 2021, with samples already available.

In the linear modes of CUR 4000, a configurable array of Hall elements enables highly accurate measurements for core-based stray-field robust sensor-module designs. The differential mode enables minimal coreless and stray-field robust system designs without shields. Read-out of the complete Hall array provides an output-offset temperature-drift below ±0.05 percent full scale. Furthermore, the sensor delivers a hysteresis-free output signal. A non-linearity error of ±0.2 percent and a noise performance of ±0.005 percent full scale allows precise current measurements with a signal bandwidth of up to 8 kHz.

TDK used proven Hall sensor technology to structure the CUR 4000. Primary characteristics, like temperature dependent gain and offset can be adjusted to the magnetic circuitry by programming the non-volatile memory. CUR 4000 is defined as SEooC ASIL-B ready, according to ISO 26262 with several on-board diagnostic functions, which builds a basis for current sensor modules with a higher ASIL level using redundancy techniques or a combination with other current sensing technologies.

CUR 4000 is available in a small eight-pin SOIC8 SMD package for less complex assembly compared to through-hole packages.

All Comments (0)