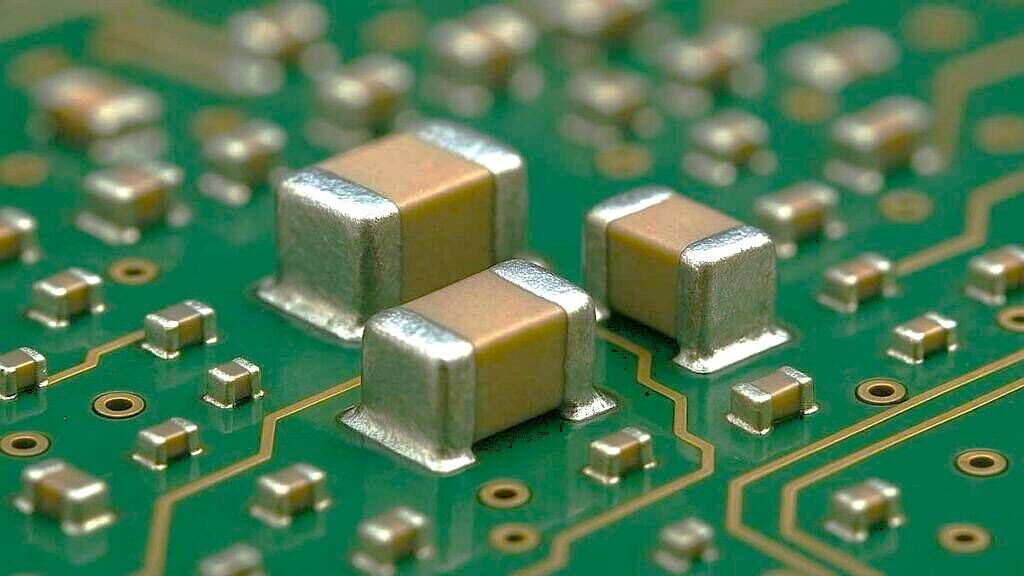

February 3, 2026 /SemiMedia/ — Samsung Electro-Mechanics is operating its multilayer ceramic capacitor (MLCC) plant in Tianjin around the clock as growing demand from the automotive sector continues to lift orders, according to sources in the passive components supply chain.

The Tianjin facility, the company’s largest production base globally, employs around 8,000 workers on rotating shifts to maintain 24-hour operations. The plant mainly produces automotive-grade MLCCs, while also supplying products to consumer electronics and server markets.

Demand for automotive MLCCs has been rising as electric vehicles gain wider adoption and vehicle electronic systems become more complex. Industry sources said the increasing number of MLCCs used per vehicle has become a key factor driving higher utilization rates at the Tianjin automotive-focused production lines.

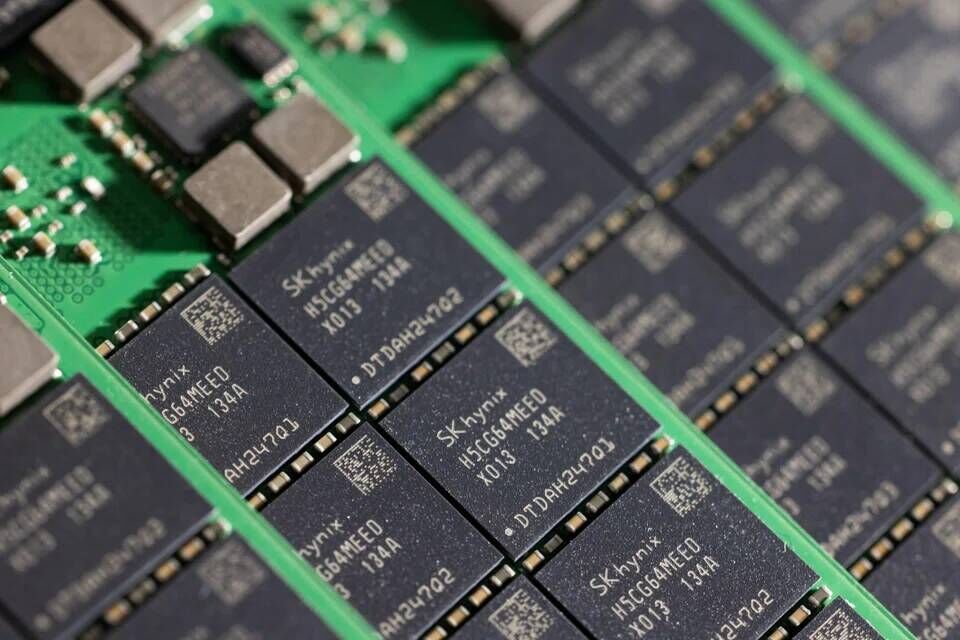

Beyond the automotive sector, expanding artificial intelligence applications and rising shipments of AI servers have also supported long-term demand for high-reliability MLCCs. Concerns over potential supply constraints have led customers to seek long-term supply agreements with major manufacturers to secure stable capacity.

Order data points to a continued recovery. Samsung Electro-Mechanics said orders at its main production sites, including Tianjin, rose by about 30% year on year in the fourth quarter of 2025. Supply chain sources added that spot prices for MLCCs have edged higher in recent weeks as demand improved.

All Comments (0)