June 11, 2025 /SemiMedia/ — NXP Semiconductors is set to phase out four 8‑inch wafer fabs—one in Nijmegen, Netherlands, and three in the U.S.—over the next decade, as it shifts production to higher‑efficiency 12‑inch fabs.

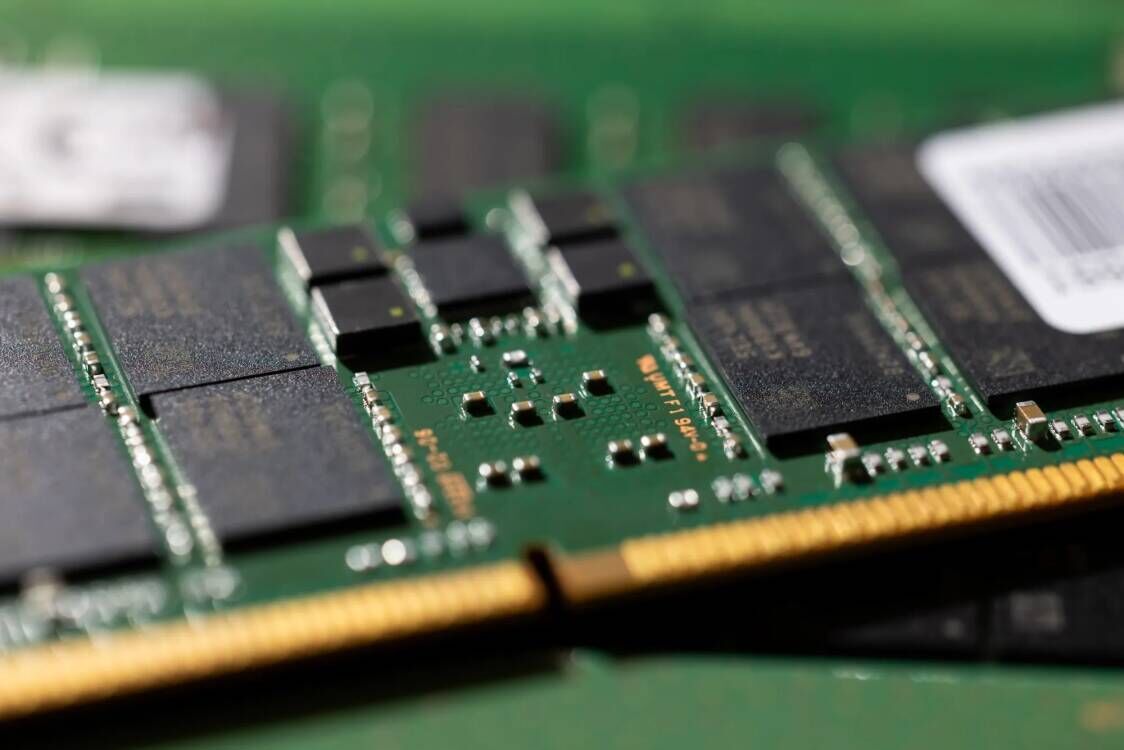

The move is driven by the economic benefits of 12‑inch wafers, which yield about 2.25 times more capacity per wafer compared to 8‑inch, resulting in significantly lower fixed and manufacturing costs. This fits into a broader industry trend toward larger wafer sizes amid surging AI and data‑center demand.

In a strategic expansion, NXP plans to leverage its joint venture with Vanguard International Semiconductor (VSMC) in Singapore, aiming for 12‑inch volume production by 2027 and targeting a monthly output of 55,000 wafers in mixed‑signal and analog chips by 2029. This facility will serve as a manufacturing hub for the Asia‑Pacific region.

Industry data indicates that global 12‑inch wafer capacity is expected to reach 9.6 million wafers per month by 2026, representing roughly 65% of silicon substrate shipments—while 8‑inch capacity accounts for around 20%.

Analysts attribute NXP’s fab consolidation to the combined pressures of market demand, production efficiency, and competitive cost structure. Although scaling up to 12‑inch fabs requires substantial investment and complex processes, NXP’s partnership and foundry strategy allow it to balance advanced node capabilities with mature process volume. Maintaining optimal cost and geographic distribution will be critical to its success.

All Comments (0)