April 4, 2025 /SemiMedia/ — Infineon’s Wuxi plant has reached a significant milestone, marking 30 years of operations in China. As Infineon’s largest IGBT production base globally, the Wuxi facility plays a critical role in advancing the company’s localization strategy, contributing to the growing demand for power semiconductors in automotive, renewable energy, industrial, and consumer electronics sectors.

In alignment with its “In China, For China” strategy, Infineon has been actively strengthening its local production capabilities to enhance supply chain resilience and accelerate innovation. “As Infineon continues to optimize its global manufacturing footprint, our Wuxi plant will play a vital role in supporting this transition,” said Yongxin Fan, Senior Vice President and General Manager of Infineon Wuxi. “By leveraging our expertise and working closely with local partners, we aim to drive efficiency, flexibility, and technological advancement.”

Expanding Localization and Strengthening the Supply Chain

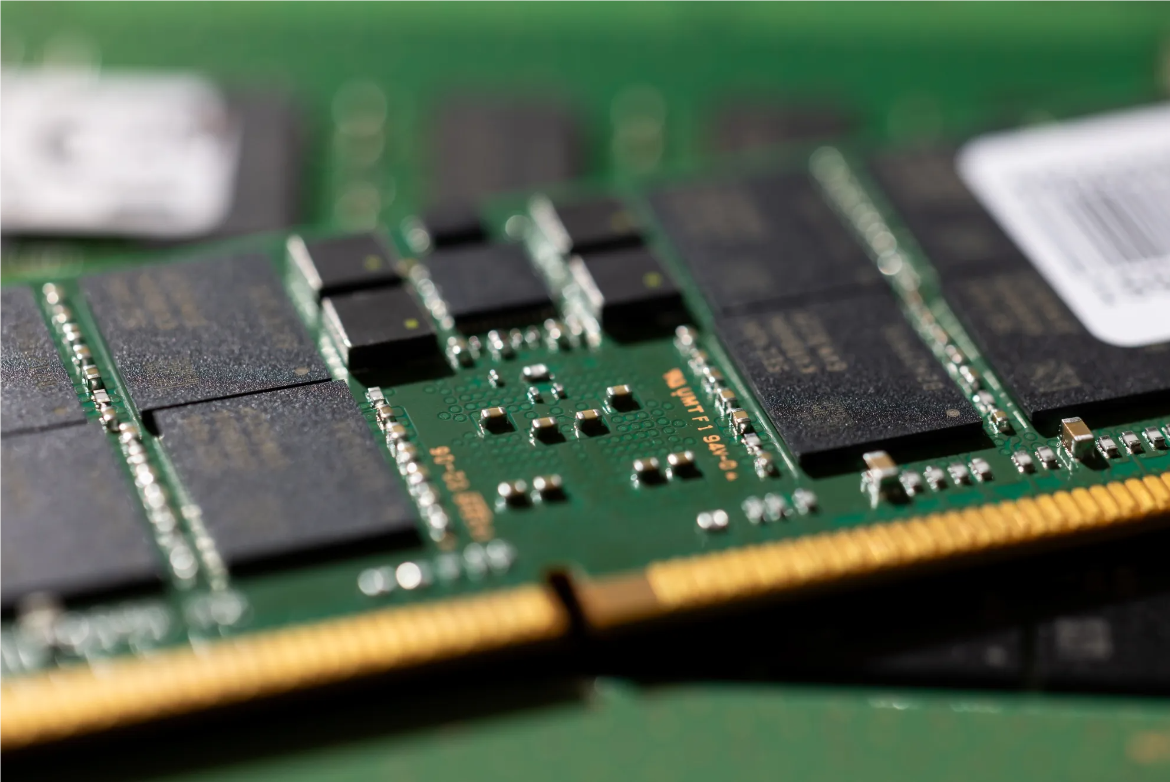

The Wuxi plant has continuously expanded its product portfolio and optimized its manufacturing processes to meet both local and international market demands. By forging strong collaborations with Chinese suppliers, Infineon has enhanced supply chain stability, ensuring smooth and efficient product delivery worldwide.

“The closer we are to our customers, the better we can serve them,” Fan emphasized. “Integrating with the local market allows us to streamline supply chains, improve logistics, and better respond to customers’ evolving requirements. Our rapid-response mechanisms ensure that we can swiftly adjust production strategies to accommodate market changes.”

Driving Smart Manufacturing and Sustainability

As a flagship smart manufacturing facility, Infineon Wuxi has implemented advanced digitalization and automation strategies to enhance production efficiency and precision. The plant has set industry benchmarks with its stringent quality control system, achieving an exceptionally low defect rate of just 2.9 per billion products.

In addition to technological advancements, Infineon is committed to sustainability. The Wuxi plant aims to achieve 100% renewable electricity usage by 2025 and has integrated resource recycling initiatives to reduce its carbon footprint. These efforts align with Infineon’s broader global mission to develop greener, more energy-efficient semiconductor solutions.

A Strategic Hub for Infineon’s Global Growth

As the global semiconductor industry faces supply chain uncertainties and increasing competition, Infineon continues to strengthen its footprint in key markets, with China playing a pivotal role in its long-term strategy. “Our Wuxi plant is not only a production facility but also a key innovation hub within our global network,” said David Poon, President of Infineon Greater China. “By investing in talent development and fostering a more integrated semiconductor ecosystem, we are reinforcing Infineon’s leadership in power semiconductors worldwide.”

The imminent opening of Infineon Wuxi’s new building further reflects the company’s commitment to long-term growth in the region. Moving forward, the plant will continue to enhance its capabilities in intelligent and low-carbon manufacturing, positioning itself as a benchmark for efficiency, quality, and sustainability. By doing so, Infineon Wuxi aims to create significant value for global customers and contribute to the sustainable advancement of the semiconductor industry.

All Comments (0)