Infineon Technologies announced the opening of a high-tech chip factory for power electronics on 300-millimeter thin wafers at its Villach site in Austria under the motto “Ready for Mission Future.” At 1.6 billion euros, the investment made by the semiconductor group represents one of the largest such projects in the microelectronics sector in Europe. The Villach site is one of the world’s most modern fabs and was opened by Infineon CEO Reinhard Ploss, Infineon Austria CEO Sabine Herlitschka along with EU Commissioner Thierry Breton and Austrian Chancellor Sebastian Kurz.

Infineon set the stage for long-term, profitable growth based on energy efficiency and CO 2 reduction at an early stage and announced the construction of the chip factory for power electronics (“energy-saving chips”) in 2018. “The new fab is a milestone for Infineon, and its opening is very good news for our customers,” Ploss said. “The timing to create new capacity in Europe could not be better, given the growing global demand for power semiconductors. The last few months have clearly shown how essential microelectronics are in virtually every area of life. Given the accelerated pace of digitalization and electrification, we expect demand for power semiconductors to continue to grow in the coming years. The additional capacities will help us serve our customers worldwide even better, including long term.”

The global chip-market situation clearly shows how important investments in innovative technologies are for the future. Today, microelectronics is the dominant technology on which all other developments, systems and technologies in the area of digitalization are based. With the expansion of its production facilities, Infineon is setting an industrial policy milestone in terms of supply security for both European industry and the global market.

The semiconductors produced in Villach will be used in numerous applications. As a result, the new factory will enable Infineon to serve the growing market for power semiconductors in electric cars, data centers as well as solar and wind energy. Arithmetically speaking, the annual capacity planned for industrial semiconductors is sufficient to equip solar systems producing a total of around 1,500 TWh of electricity – roughly three times the annual power consumption in Germany.

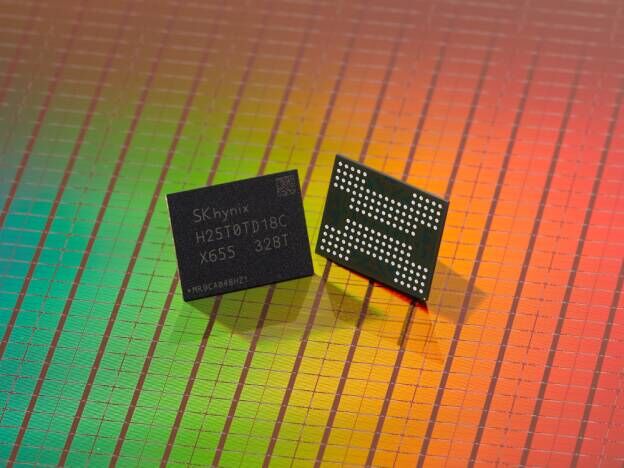

Sabine Herlitschka, the CEO of Infineon Technologies Austria AG, said: “With this investment, Infineon has demonstrated that it is also possible to build attractive production sites in Europe in the highly competitive microelectronics sector. We are setting new standards with this investment. The energy-saving chips from Villach will become important core elements for the energy transition. We are thus making a relevant contribution to the European Green Deal and beyond. We are ‘Ready for Mission Future.’” Infineon is going one step farther. Jochen Hanebeck, a member of the Management Board and Chief Operations Officer of Infineon, said: “Infineon now has two large power semiconductor manufacturing sites for 300-millimeter thin wafers, one in Dresden and one in Villach. Both sites are based on the same standardized production and digitization concepts. This allows us to control the manufacturing operations at the two sites as if they were one factory. We increase productivity and create additional flexibility for our customers. This is because we can quickly move production volumes for different products between the sites and thus respond even faster to their needs. With the virtual megafactory, Infineon is setting a new benchmark in 300-millimeter manufacturing. This makes further increases in resource and energy efficiency possible, as well as optimization of the environmental footprin

All Comments (0)