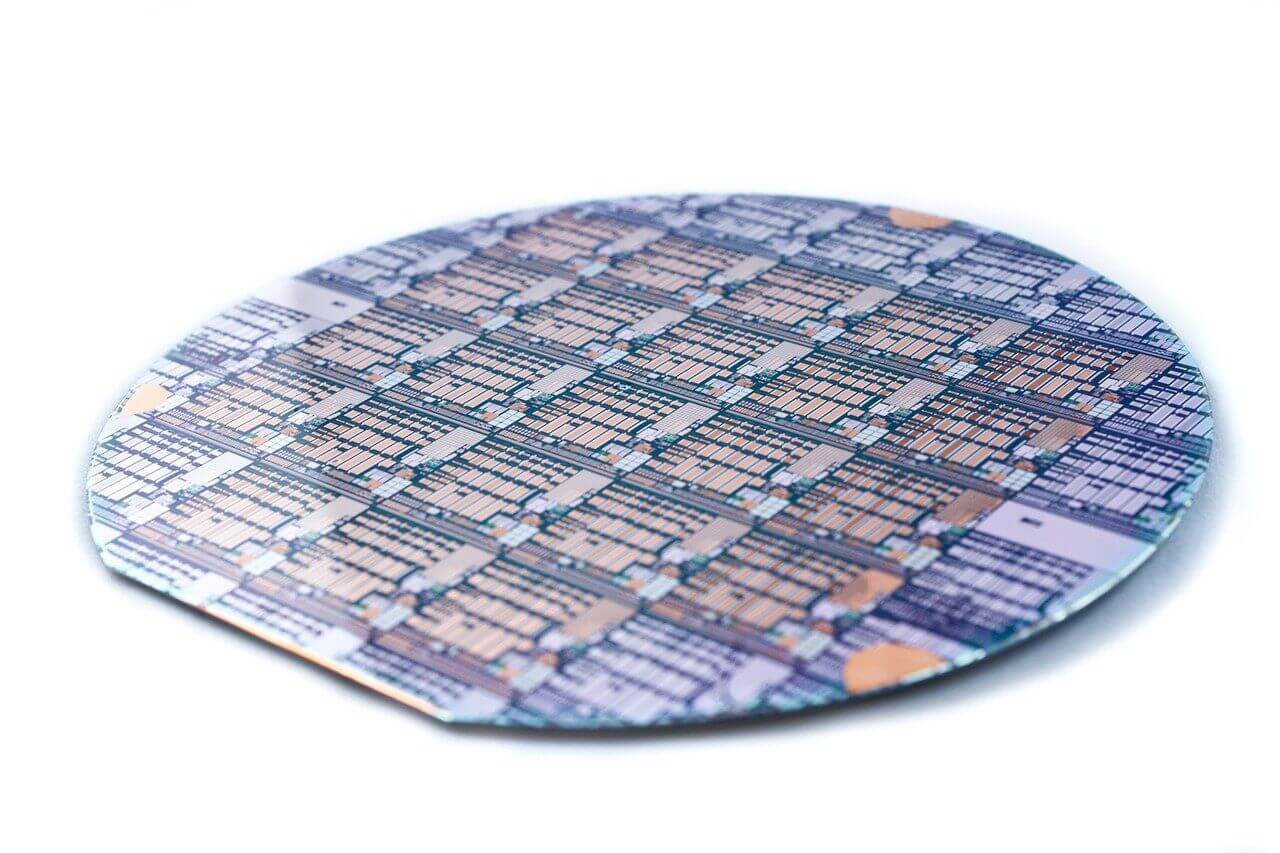

Leuh Fang, chairman of Vanguard International Semiconductor Corporation (VIS), said on the 11th that under the simultaneous growth of various demands, it is expected that the shortage of 200mm wafers will continue until the third quarter of next year. In the case of insufficient production capacity, VIS is currently still undergoing phased expansion. The clean room has been prepared, and production can be expanded as long as the production equipment is installed.

Leuh Fang pointed out that although global GDP has been hit by the Covid-19 pandemic, semiconductor demand has grown against the trend, resulting in a surge in semiconductor demand this year. With proper epidemic prevention and control in various countries and regions, the industry has a positive attitude towards next year's semiconductor outlook.

Regarding the shortage of 200mm wafers this year, Leuh Fang pointed out that the main reasons include the huge increase in demand for power management chips from 5G mobile phones, and the epidemic has led to a substantial increase in the demand for technology products such as remote work, education, and medical care. In addition, automotive electronics also began to rebound in the second half of this year, and demand for automotive semiconductors increased significantly.

Leuh Fang said that the current demand for products such as power management ICs, driver ICs and image sensors is the largest, and the demand for automotive electronics has also increased significantly. It is expected that the shortage of 200mm wafer foundry will continue at least until the first half of next year or even the third quarter.

However, Leuh Fang also believes that during the period when 200mm wafers are in short supply, there may be repeated orders or over-orders, which may also affect subsequent inventory and customer procurement plans. Therefore, it is not yet possible to predict how long the current strong demand will last.

All Comments (0)